ONTARIO

Aggregates used in Ontario for provincially funded projects must meet the requirements of the appropriate provincial standard:

OPSS.PROV 1001 Aggregates – General

OPSS.PROV 1002 Aggregates – Concrete

OPSS.PROV 1003 Aggregates – Hot Mix Asphalt

OPSS.PROV 1004 Aggregates – Miscellaneous

OPSS.PROV 1005 Aggregates – Waterbody

OPSS.PROV 1006 Aggregates – Surface Treatment

OPSS.PROV 1010 Aggregates – Base, Subbase Select Subgrade and Backfill Material

These standards are designed to achieve a certain durability of construction. They can be very region specific since soil and weather conditions vary from one region to another. The Standards are very specific when it comes to Blast Furnace Slag and Steel Slag. Currently, Steel Slag is not permitted for use other than open graded applications. Each OPSS lists the required Property/Physical Testing of each aggregate and is listed under each MTO Laboratory Testing number within. Each OPSS has an LS-### along with the grading requirements for each product it specifies.

Steel Slag is not permitted for use as a Hot Mix Asphalt Aggregate in Ontario funded projects primarily due to expansion properties when wet. The slag industry throughout North America has done and continues to do research and trials to allow steel slag aggregate with a maximum expansion by test of no more than 1%.

Autoclave Testing Equipment for Expansion at Levy Lab, Portage, Indiana

The ban of steel slag aggregates in Provincial projects does not prevent the product from being specified for local municipal or private projects as defined by the project engineer. Steel slag aggregate has superior skid resistance to gravel and other stone aggregates due to its angular shape and non-polishing properties and many municipalities are specifying its use with a maximum limit of 1% expansion.

QUEBEC

Road building projects in Quebec must meet the BNQ and the equivalent of the Ontario OPSS specifications. Slag use is also subject to environmental regulations so its use must provide the following:

- Meet or exceed specification for intended use.

- Meet authorizations from the Ministry of the Environment.

- Approval from the project engineer based on items 1 and 2.

The MTQ allows the use of EAF Steel Slag only. The aggregate must meet spec BNQ 1A and must not be used on a weight sensitive structure not meant to accept additional fixed weight.

The private sector uses EAF Steel Slag Aggregate under home branded high end mixes

Michigan, USA

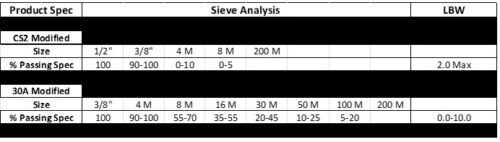

Blast Furnace Slag Aggregate is used in Hot Mix Asphalt in Michigan and other States. The product must meet the following Sieve Analysis:

L.A. Abrasion test is performed on the aggregate every 5 years and A.W.I. is provided on request.

Inter-Ontario Equipment in Sault-Ste-Marie processes all the Air Cooled Blast Furnace Slag from Algoma Steel into gradations meeting the requirements of USA Specs. After screening and quality checks, the slag is loaded onto lakers for furtherance to ports in the USA.